PRODUCTION PROCESS

Stamping

Stainless steel raw materials are stamping with different design mould.

Straight Adjustment

Make sure all the blade are straght though the straight adjustment machine.

Heat Treatment

processes like hardening, tempering, and annealing are employed to enhance durability, edge retention, and overall performance.

Rough Grinding

Initial machining process used to remove large amounts of material from the metal part.

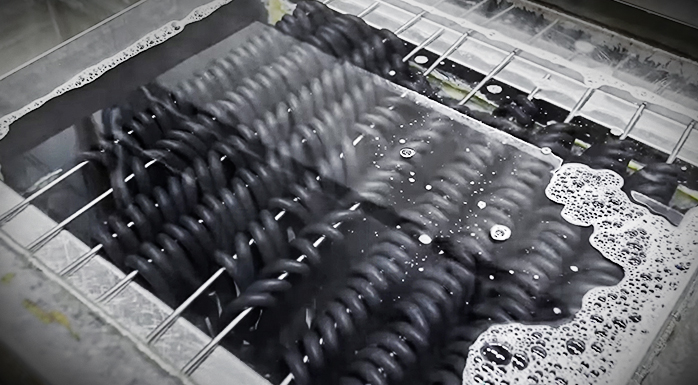

Water Grinding

A precision process for sharpening knives and scissors,reduce friction, prevent overheating, and achieve a finer, smoother edge and cutting performance.

Polishing

Polishing sharpens and refines blades, enhancing durability and cutting efficiency for knives and scissors.

Injection

Creates ergonomic, durable handles for knives, scissors, and kitchen tools. Using high-pressure plastics, it ensures comfort, grip, and long-lasting performance.

Ultrasonic Cleaners

efficiently remove wax and contaminants from knives and scissors during manufacturing, ensuring precision and cleanliness through high-frequency sound waves.

Setting

Skilled technicians ensure precise assembly by adhering to diverse inspection standards. Their expertise guarantees quality, consistency, and optimal performance for each product.

Quality Check

Strict quality check ensures each product meets precise standards, enhancing reliability, safety, and customer satisfaction. It involves thorough inspections at every production stage.

Final Clearing

s involves thoroughly drying the items to remove moisture, followed by the application of anti-rust oil to protect and preserve the metal surfaces from corrosion.

Packing

To meet client needs, various packaging methods are meticulously employed, ensuring products are securely and attractively packed for safe and customized delivery.