Ice tray manufacturing is a fascinating process that combines innovation and precision to create essential kitchen tools. This industry focuses on producing high-quality molds for ice cubes, spheres, and other shapes that enhance everyday experiences, from chilling beverages to creative culinary presentations.

The Role of Ice Cube Trays Suppliers

In the realm of ice tray manufacturing, ice cube trays suppliers play a crucial role in ensuring a steady supply of durable and efficient products. These suppliers source materials like food-grade plastic or silicone, allowing manufacturers to meet diverse consumer needs. For instance, a reliable ice cube trays supplier can provide trays that are easy to use and clean, supporting both home users and commercial kitchens in maintaining optimal performance.

Exploring Silicone Ice Trays in Modern Manufacturing

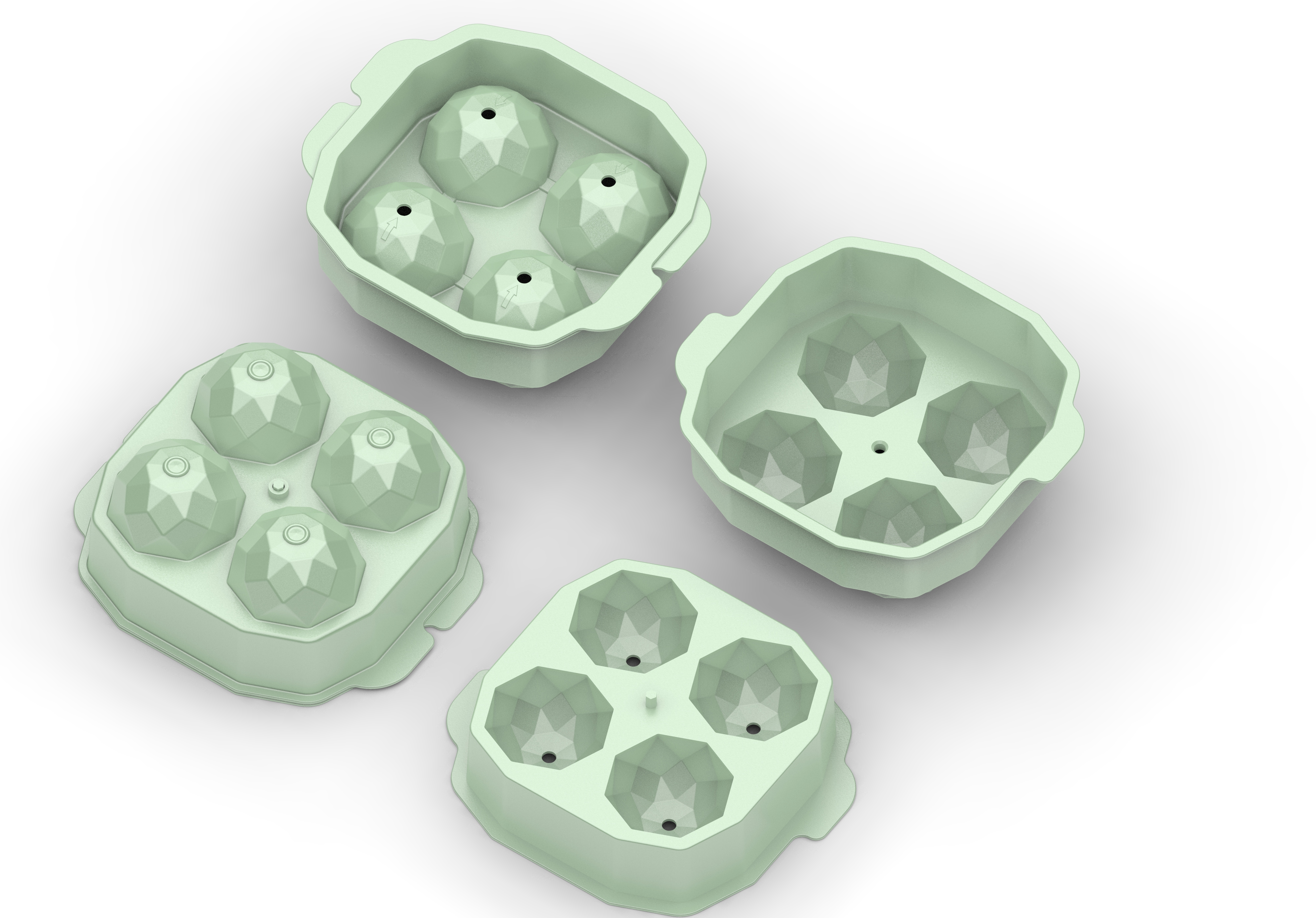

Silicone ice trays have revolutionized ice tray manufacturing due to their flexibility and durability. Unlike traditional plastic trays, silicone ice trays offer easy removal of ice without cracking, making them ideal for intricate designs like spheres. This material's resistance to extreme temperatures ensures longevity, appealing to those who prioritize sustainability and ease of use in their kitchen gadgets.

Benefits and Innovations in Ice Tray Design

Beyond basic functionality, innovations in ice tray manufacturing, such as the sleek Ice Ball Maker, elevate the user experience. This product, crafted from durable materials, allows for the creation of perfect ice spheres that chill drinks slowly and reduce dilution. By integrating such designs, manufacturers are not only meeting market demands but also enhancing aesthetic appeal, making ice trays a staple for bar enthusiasts and everyday users alike.